3D printers can transform creative ideas into reality and provide users the ability to create various objects of interest i.e. figurines, household accessories, mobile accessories, watches etc. When we look at things from an industrial perspective, 3D printing technologies, especially metal 3D printers, are seriously improving manufacturing in many areas, namely automotive, aerospace, architecture/design, medical, military manufacturing and more.

Metal 3D printers are changing some of the key industries, allowing for more custom-made complex models to be made which traditional manufacturing methods may not have achieved. In the medical field this is seen with companies specialising in the manufacturing of patient implants required for surgery.

In Aerospace, 3D printing became one of the cornerstone technologies to be used for the development of prototype models, but times have changed and now aircraft parts are also being 3D printed – GE Aviation and Airbus have been early adopters of this.

In as far as the automotive industry, complete car parts have been made using 3D printing and there are rumours of complete cars being manufactured with this technology in the near future. As we make these points of comparison, it becomes undoubtedly clear how pivotal this advanced form of additive manufacturing is, in enhancing the production and manufacturing process. 3D printing is currently streamlining manufacturing, and this could potentially lead to huge savings on traditional production and manufacturing time and costs in the future.

Metal 3D printing is something that individuals working in the mentioned industries and investors may wish to know more about. For the purposes of this article we’ll look at some of the top metal 3D printers on the market, the original report has 44 metal 3D printers for your perusal which you can review here. Naturally the pricing of these printers ranks substantially higher and considering the industries they’re used in the most aggressively, it’s understandable.

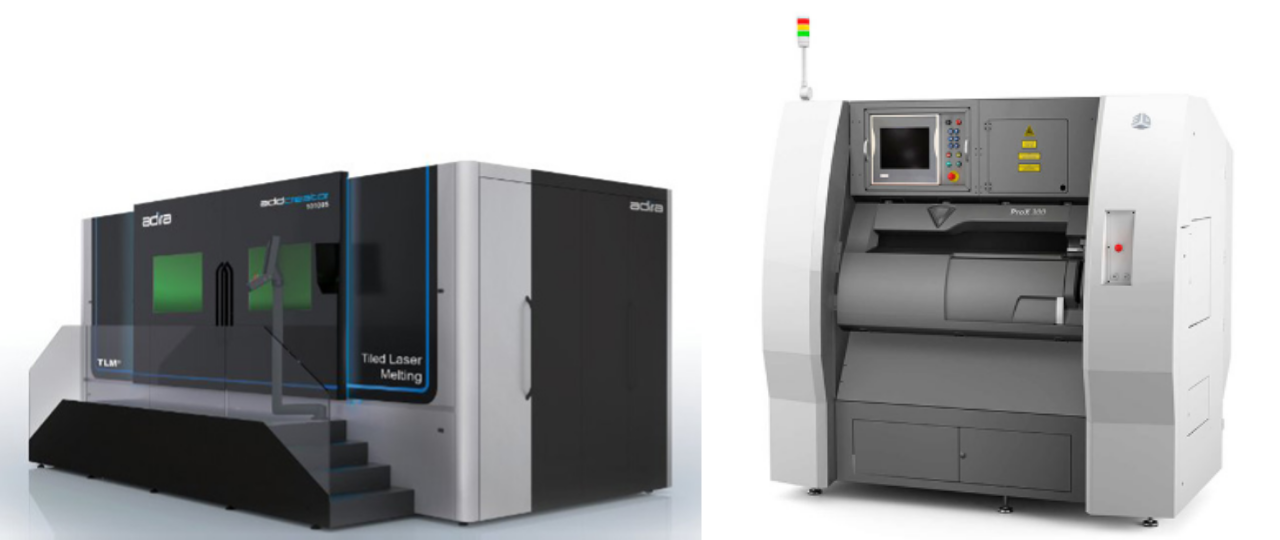

3D Systems ProX DMP 300

Build Volume(mm): 250 x 250 x 330

Price: More than $250K

The 3D Systems ProX DMP 300 was designed for manufacturing larger sized ceramic and dense metal components. It offers high performance with greater speed for production and minimal waste of print materials. The machine has reportedly already been used in automotive manufacturing and assisted the process of manufacturing a custom made pulley for a Mitsubishi Evo race car in the past.

ADIRA AddCreator

Build Volume (mm): 1000 x 1000 x 500

Price: $100K – $250K

Described as a very large format industrial 3D printer, the ADIRA AddCreator manufactured by Portugal based ADIRA is capable of producing large-size metallic components/parts with its tiled laser melting technology. It uses metal powder material and is based on a powder bed fusion system which spreads into a vat. It’s said to be suitable for the manufacture of professional applications in the aerospace and automotive industries.

BeAM Modulo 400

Build Volume (mm): 600 x 400 x 400

Price: More than $250K

Offering directed energy deposition (DED), the BeAM Modulo 400 is classed as an additive manufacturing (AM) system, suitable for the production of small parts as well as the maintenance or adding of material to existing parts. It has been chosen by several institutes for research and development (R&D) in the areas of materials development to medicine and manufacturing testing. At present it’s also in use at the Oak Ridge National Laboratory in Tennessee.

Sciaky EBAM 300 Series

Build Volume (mm): 5791 x 1219 x 1219

Price: More than $250K

The Sciaky EBAM 300 Series uses Electron Beam Additive Manufacturing (EBAM), with its capacity for large volume builds, it also boasts fast deposition rates. Recent reports suggest that the EBAM system will be used to support America’s defence and power generation programs. It’s said to be capable of producing large parts for land, sea, air and space applications.

SPEE3D LightSPEE3D

Build Volume (mm): 300 x 300 x 300

Price: $650,000

The SPEE3D LightSPEE3D has been described as the fastest metal 3D printer, it’s being used to produce metal parts at a fraction of the time and cost to demonstrate the existing opportunities to generate low cost metal parts.

MarkForged Metal X

Build Volume (mm): 300 x 220 x 180

Price: $99,500

Reportedly one of the first 3D printers to use the extrusion process for metal printing the Markforged Metal X conquered the challenge that previously no one thought would be possible – metal 3D printing through extrusion. The Metal X model is based on the company’s signature Atomic Diffusion Additive Manufacturing (ADAM) technology. Feedback in the form of case studies will be released where users of the Metal X will share their experience with it, the US Marine Corps is said to be on the list of entities that will share their experience with the machine.

Fabrisonic Sonic Layer 4000

Build Volume (mm): 1016 x 610 x 610

Price: More than $250K

Fabrisonic is famous for its ultrasound additive manufacturing (UAM) technology and the company has become attractive to NASA over the years, as they’ve worked with them a few times. At the root of it, the Sonic Layer 4000’s technology consists of using ultrasonic sounds to merge layers of metal foil, the process is described as additive and subtractive manufacturing.

ExOne S-Print

Build Volume (mm): 800 x 500 x 400

Price: More than $250K

Made by German manufacturer ExOne, the S-Print’s binder jetting technology which follows an additive manufacturing (AM) process, involves the joining of a liquid binding agent to powder particles, it automatically creates complex sand cores and moulds with CAD data, making the need for physical patterns to create cores or moulds null and void and the manufacturing process all the more seamless.

AIM3D ExAM 255

Build Volume (mm): 255 x 255 x 255

Price: $100K-$250

The ExAM 255 is reportedly the first 3D printer that uses CEM (Composite Extrusion Modelling) to produce metal parts/components. The process involves the extrusion of material which is then bound together with a plastic component. With a pellet extruder, it can 3D print a wide range of other materials including plastic.

Sodick OPM350L

Build Volume (mm): 350 x 350 x 350

Price: More than $250K

The Sodick OPM350L’s main function it to produce high quality metal components for moulding. Their hybrid metal 3D printing technology combines laser sintering and milling to print and process simultaneously. It stands out against other multi laser beam systems because of its ‘Parallel Mode’ feature which allows it to use multiple laser beams in a quadrant if necessary.

We’ve only covered 10 of the 44 metal 3D printers featured in the original article. For more detailed information on the specifications and features of these machines, you can visit Aniwaa to review each of these metal 3D printers and more at your leisure.