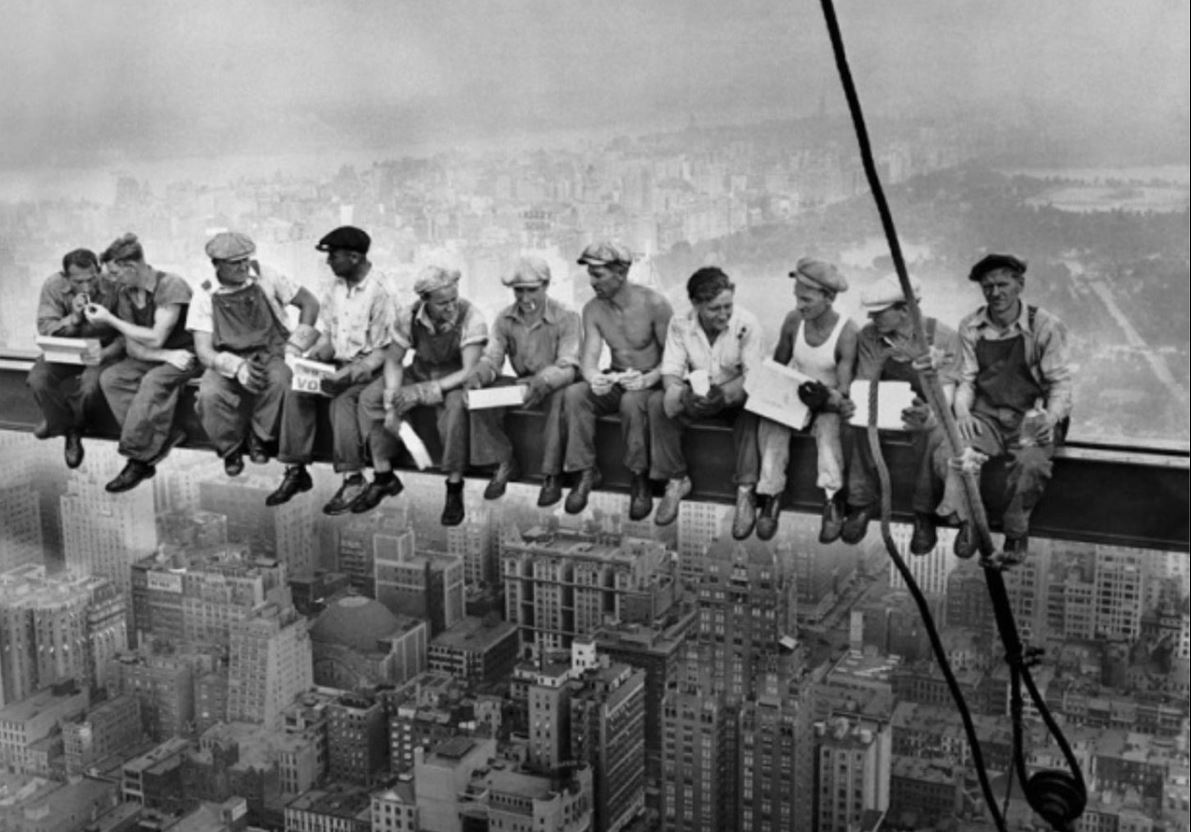

It’s hard to believe, but there are more construction-related fatalities today — even with our more advanced safety technology — than there where when this iconic photo was taken in 1932. During the construction of the Empire State Building, there were only five fatalities. In 2017, there were 4,674 construction-related fatalities. New technology is making construction equipment safer, but this comes at a cost. How is new technology disrupting the construction equipment industry?

New Technologies

It seems like new technologies are cropping up every day when it comes to the construction industry. 3D printers are making an appearance and can construct an entire concrete building in 24 hours. RFID (radio frequency identification) helps both rental companies and equipment owners keep track of their machinery, either by attaching an RFID tracker to the exterior or embedding it in the frame.

There are apps for nearly everything, from recording OSHA-required documents to capturing contract signatures. New heavy machinery comes equipped with smart alerts and IoT technology to help maintenance crews predict breakdowns before they even happen.

Increasing Costs

The global market for construction equipment is expected to pass $170 billion by 2024. While part of this increase is due to growth in the construction industry, a significant portion of this increase is due to changes in technology.

Most new construction equipment comes equipped with more expensive technologies, like remote tracking, GPS, sensors and even real-time monitoring. While this does make the machine safer and serve to protect an owner’s investment, new technology is more expensive, which in turn increases the price of the equipment. This has lead many companies to abandon traditional ownership models in favor of renting.

The Rise of the Rental

Purchasing new equipment is a significant investment. Even leasing something can cost a company hundreds or thousands of dollars a month during the lease. The return on investment drops considerably for specialty pieces that may only be used a handful of times every year.

Nearly every piece of industrial or construction equipment can be rented for a day, a week, or the entire length of a construction project, depending on the needs. For companies that generally do their work on the ground, a boom lift is something that might only be necessary for special projects — purchasing one puts the company on the hook for storage and maintenance costs because they do still need to be maintained even when they aren’t being used.

The global construction equipment market isn’t the only one that is expected to grow in the next few years. Between 2018 and 2024, the equipment rental market will rise 4 percent. While some of this growth is driven by DIYers who rent the equipment that they need to do projects at home, the majority of the increase is due to the growing number of business owners who are renting rather than buying equipment.

There is also a growing demand for rental equipment in developing countries and emerging economies, where construction companies might not have the buying power to purchase or lease their equipment. The machinery is still necessary because construction projects will continue even if the machines aren’t available. The demand for fast urbanization is fueling the rental market overseas.

Closing Thoughts

We’ve come a long way since construction workers enjoyed their lunch sitting on a girder, high above the New York City skyline, but that doesn’t mean that we can be lax when it comes to construction safety and equipment. New technology is hoping to make these jobsites safer, but it can only do that if businesses can afford to have the equipment for their project. Renting is a viable option for any company that may need a piece of specialty equipment for one job, or who might not have the buying power to purchase their equipment.